DETAILS

- Plate heating type

- Bulletproof tempered glass window

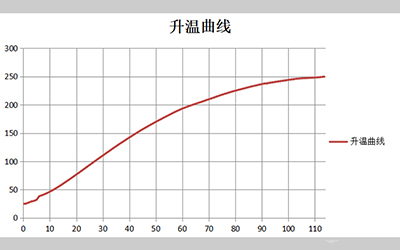

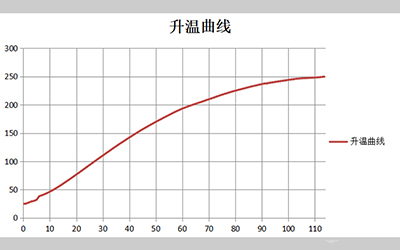

- Heating curve

Vacuum drying ovens are widely used in research applications such as biochemistry, chemical pharmacy, medical and health, agricultural research, environmental protection, etc., for powder drying, baking, and disinfection and sterilization of various glass containers. It is especially suitable for fast and efficient drying treatment of dry heat sensitive, easily decomposed, easily oxidized substances and complex composition items.

1. This vacuum drying oven adopts independent partition heating, multi-segment PID full temperature range on the touch screen, program temperature control, accurate and reliable temperature control, uniform and stable heating.

2. Bullet-proof tempered glass observation window, the objects inside are clear at a glance when working, and inert gas can be rushed into the inside.

3. The closing tightness of the box door can be adjusted, and the synthetic silicon door sealing ring is integrally shaped to ensure high vacuum in the box.

4. Storage, heating, testing, and drying can be carried out in an environment without oxygen or full of inert gas, and will not cause oxidation.

5. The heating method is flexible and changeable. Single-layer or double-layer heating mode can be selected.

6. The controller can choose two operating modes: fixed value or program

7. The heating rate can be set during constant value operation, and three modes of start timing, constant temperature timing and shutdown timing can be selected.

8. When the programme is running, it can call the corresponding number of the programme according to different test requirements.

9. Each programme can set the temperature and time of each step flexibly.

10. Real-time temperature curve recording, which is convenient for users to see the temperature rise process intuitively.

11. The instrument has built-in intelligent temperature control algorithm, which can ensure the accuracy of temperature control in any temperature range, and the built-in multi-layer password protection prevents the user from changing the internal parameters due to misoperation.

Model | LDZ24T | LDZ53T | LDZ91T | ||

Method | independent temperature limiter, 2 partitions | ||||

Performance | Operating temperature range | RT+10-250℃ | |||

Ultimate vacuum | <133PA | ||||

Temperature resolution | 0.1℃ | ||||

Temperature fluctuation | ±1℃ | ||||

Heating time | from room temperature to the highest use temperature ≤ 40 minutes | ||||

The uniformity of temperature control of the partition | ±0.5℃ | ||||

Composition | Interior | stainless steel | |||

Exterior | cold plate spraying | ||||

Thermal insulation material | aluminum silicate fiber | ||||

Heater | independent partition heating | ||||

Observation window | bulletproof tempered glass | ||||

Vacuum gauge | pointer type | ||||

Rated power | 0.6 kw | 1.0kw | 1.4kw | ||

Controller | Temperature control mode | 5.0-inch LCD touch screen, multi-segment PID full-temperature program temperature control | |||

Temperature setting method | touch type | ||||

Temperature display method | liquid crystal display | ||||

Timer | 999 hours for fixed value operation; 999 hours/step for programme operation | ||||

Operation function | fixed value operation, timing operation, automatic stop, program operation | ||||

Program mode | 99 segments, 16 steps | ||||

Additional functions | deviation correction, power failure compensation, real-time curve recording | ||||

Sensor | Pt100 | ||||

Safety device | self-diagnostic circuit, abnormal temperature sensor, independent temperature limiter | ||||

Specifications | Internal dimensions (W * D * H)(MM) | 300*300*270 | 415*370*340 | 450*450*450 | |

External dimensions (W * D * H)(MM) | 517*495*660 | 632*566*736 | 667*646*841 | ||

Outer packaging size (W * D * H)(MM) | 679*609*767 | 794*679*842 | 829*759*947 | ||

Inner volume | 24 L | 53L | 91L | ||

Shelf load-bearing capacity | 15 kg | ||||

Number of clapboard layers | 2 layers | ||||

Space between partitions | 130 mm | 135mm | 175mm | ||

Suction port | φ10 mm | ||||

Exhaust port | φ10 mm | ||||

Power supply (50/60Hz) rated current | 220V 50Hz | ||||

Net weight/Gross weight | 40/52kg | 70/90kg | 90/115kg | ||

Configurations can be added | 485 interface, printer, vacuum pump, external communication, remote control, mobile phone control. | ||||

We hebben een standaard productiewerkplaats en een compleet productieteam. Ze produceren altijd een serieuze en verantwoordelijke houding om elk product te produceren. Ons R & D-team bestaat uit professionele ingenieurs met meerdere aspecten, zoals ontwerpingenieur, technologiespecialist, gekwalificeerde specialist en procescontrolemanager, enz. Onze gekwalificeerde specialisten realiseren strikt het uitgebreide procestoezicht op basis van ons kwaliteitsprocescontrolesysteem, dat het ontwerp van producten bevat , onderzoek en ontwikkeling, testen, productie, kwaliteitsinspectie en verpakking.

Onze laboratoriuminstrumenten en -apparatuur worden gebruikt in veel wetenschappelijke laboratoria, wetenschappelijke onderzoeksinstellingen, universiteiten, ziekenhuizen, centra voor ziektebestrijding en andere instellingen, en worden gecombineerd met vele bekende biofarmaceutica, nieuwe energie, elektronicabedrijven, voedselverwerking, milieubescherming, enz. Samenwerking tussen bedrijven, onze stabiele en betrouwbare producten worden geëxporteerd naar meer dan 120 landen over de hele wereld en worden door hen zeer erkend, geloof LABOAO, we groeien samen!