FEATURES

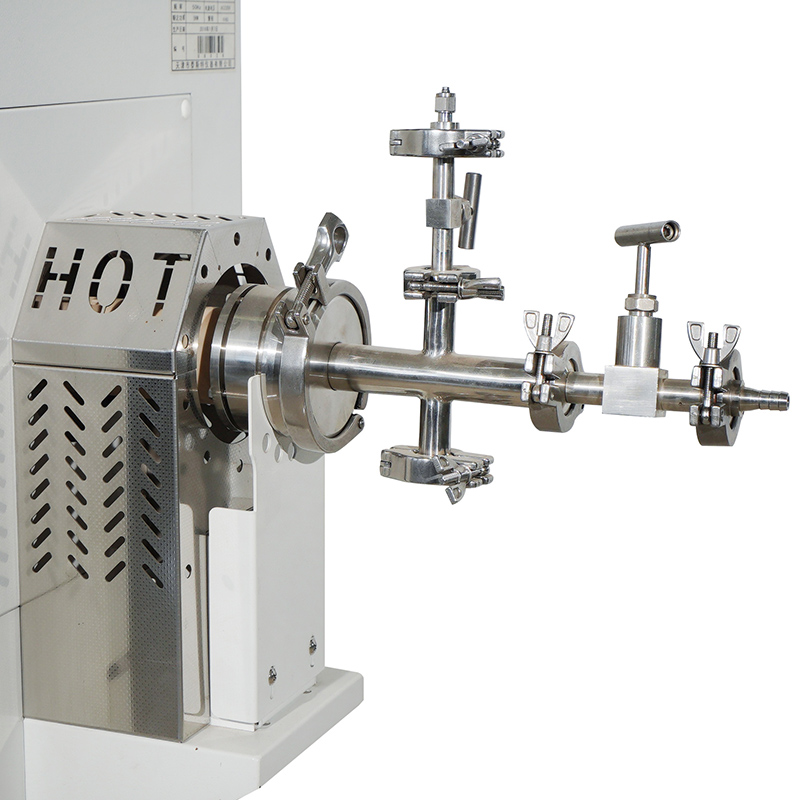

1. Quick connection flange structure is adopted for gas path connection, which is convenient for loading and unloading, and can be completed with only one clamp.

2. The furnace is made of polycrystalline mullite fiber by vacuum adsorption, with uniform temperature field and energy saving of more than 50%.

3. Independently developed air diversion heat insulation technology ensures the service life and constant temperature effect of all parts in the box.

4. Start the electric furnace, and the exhaust fan will run automatically at the same time. After the test, the exhaust fan will continue to run until the temperature of the furnace body is lower than 60 ℃, and the exhaust fan will stop automatically, effectively protecting the surface of the furnace body.

5. The gas circuit assembly is made of 316 stainless steel of food grade, with good corrosion resistance, atmospheric corrosion resistance, high temperature resistance, and non-magnetic.

6. Automatic power-off, over temperature protection and leakage protection to ensure the safety of use.

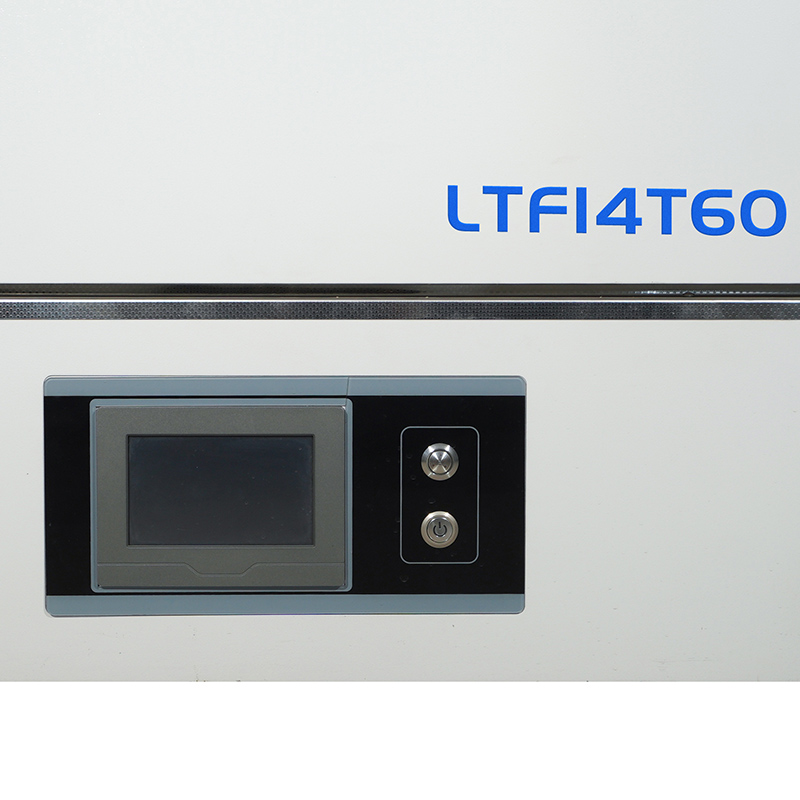

7. Imported program temperature control system, 4 curves, programmable 40 segment program temperature control, touch screen is 7 inch screen, built-in 50 formulas, 50 programs, formula name can be set by users, formula can be added, deleted and transferred at will.

8. The circuit adopts continuous heating output mode, double circuit power supply, strong and weak current wiring separately, which improves the stability of the system.

9. The heating module adopts DC signal to adjust the output power, so as to avoid the interference of induction current to the control signal.

10. Low pressure metal button is selected as the operation button, with its own status indicator, which is safe and intuitive.

11. It can automatically compensate the temperature control effect caused by temperature or aging on the resistance value of silicon carbide rod, so as to avoid the inaccuracy and danger of manual adjustment.

ONZE FABRIEK

We hebben een standaard productiewerkplaats en een compleet productieteam. Ze produceren altijd een serieuze en verantwoordelijke houding om elk product te produceren. Ons R & D-team bestaat uit professionele ingenieurs met meerdere aspecten, zoals ontwerpingenieur, technologiespecialist, gekwalificeerde specialist en procescontrolemanager, enz. Onze gekwalificeerde specialisten realiseren strikt het uitgebreide procestoezicht op basis van ons kwaliteitsprocescontrolesysteem, dat het ontwerp van producten bevat , onderzoek en ontwikkeling, testen, productie, kwaliteitsinspectie en verpakking.

KLANTGEVALLEN

Onze laboratoriuminstrumenten en -apparatuur worden gebruikt in veel wetenschappelijke laboratoria, wetenschappelijke onderzoeksinstellingen, universiteiten, ziekenhuizen, centra voor ziektebestrijding en andere instellingen, en worden gecombineerd met vele bekende biofarmaceutica, nieuwe energie, elektronicabedrijven, voedselverwerking, milieubescherming, enz. Samenwerking tussen bedrijven, onze stabiele en betrouwbare producten worden geëxporteerd naar meer dan 120 landen over de hele wereld en worden door hen zeer erkend, geloof LABOAO, we groeien samen!