DETAILS

- Multi-function control panel

- Safety glass and safety lock

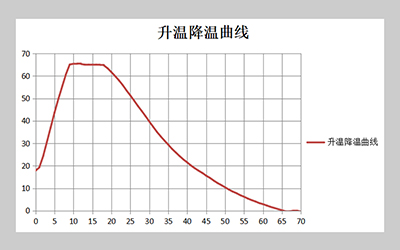

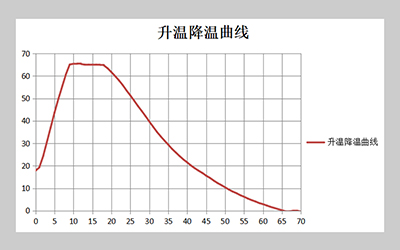

- Heating curve

This series of products has an accurate temperature and humidity control system that provides the various environmental simulation conditions required for industrial research and biotechnology testing. Therefore, it can be widely applied to sterility tests such as medicine, textile, food processing, stability inspection, raw material properties of industrial products, product packaging, product life and other tests.

1. Independent humidification for humidity control

2. LCD multi data full screen display, power failure memory, power failure compensation

3. Convenient operation, constant value operation, regular operation and automatic stop

4. Special function key to realize temperature setting

5. Auxiliary menu, realize over rising alarm, deviation correction and menu locking

6. Forced air supply by centrifugal turbine makes the temperature more uniform

7. Power off protection, parameter memory and call recovery

8. Compressor overload protection

Functionality

1. LCD 30 segment program control, repeated step, step operation

2. Loop self diagnosis, sensor fault alarm, upper and lower line over temperature alarm

3. Intelligent defrosting

4. Monitor the timing

5. Over lift preventer

Model | LWS-70B/ LWS-70BX | LWS-150B/ LWS-150BX | LWS-250B/ LWS-250BX | |

Mode | Forced convection | |||

Performance | Temperature control range | No humidification: 0-65℃ With humidification: 10-65℃ | ||

Temperature resolution | 0.1℃ | |||

Constant temperature fluctuation | High temperature: ±0.5℃ Low temperature: ±1℃ | |||

Temperature uniformity | ±1℃ | |||

Humidity control range | 45%-90%RH | |||

Humidity fluctuation | ±5% | |||

Constitute

| Interior decoration | Mirror stainless steel | ||

Exterior decoration | Cold rolled steel sheet, surface coating | |||

Thermal insulation material | polyurethane | |||

Heater | Stainless steel heating pipe | |||

Rated power | 0.7kw | 1.0kw | 1.4kw | |

compressor | Air cooled hermetic compressor | |||

Cryogen | R134A | |||

Humidity control mode | Automatic | |||

Defrosting structure | Type B: manual; type BX: automatic | |||

Lead hole | One with inner diameter of 52mm | |||

Controlled external power supply | External one | |||

Ultraviolet sterilization | YES | |||

Controller | Temperature control mode | 30 Segment LCD program | ||

Temperature setting mode | Touch the button to set | |||

Temperature representation | Measuring temperature display: LCD upper display; setting temperature display: LCD lower display | |||

Timer | 0-99.9h*30 (with timing waiting function) | |||

Operation function | Type B: fixed value operation, timing operation, automatic stop | |||

BX type: program running | ||||

Program mode | Standard | |||

Additional functions | Type B: deviation correction, menu key locking, power failure compensation, power failure memory | |||

Type BX: there are also over rising preventer, cumulative timing, loop self diagnosis and intelligent defrosting | ||||

Sensor | Pt100 | |||

Safety device | Type B: over rise alarm and overload protection; type BX: with over rise preventer and loop self diagnosis | |||

Specifications

| Internal dimensions (mm) | 420*350*500 | 500*400*750 | 500*500*950 |

Dimensions (mm) | 570*560*1073 | 640*620*1260 | 640*710*1463 | |

Outer package size | 720*720*1120 | 790*770*1380 | 800*870*1580 | |

Internal volume | 70L | 150L | 250L | |

Diaphragm bearing | 15kg | |||

Number of diaphragm layers | 5 | 9 | 12 | |

Diaphragm spacing | 60mm | |||

Rated current | AC220V/2.3A | AC220V/3.6A | AC220V/5.5A | |

Net / gross weight | 65/83 | 86/106 | 100/127 | |

Accessories | Partition | 2 | ||

Partition frame | 4 | |||

Configuration can be increased | Diaphragm, RS485 interface, printer, recorder, external communication, remote control, wireless SMS alarm, U disk data storage | |||

We hebben een standaard productiewerkplaats en een compleet productieteam. Ze produceren altijd een serieuze en verantwoordelijke houding om elk product te produceren. Ons R & D-team bestaat uit professionele ingenieurs met meerdere aspecten, zoals ontwerpingenieur, technologiespecialist, gekwalificeerde specialist en procescontrolemanager, enz. Onze gekwalificeerde specialisten realiseren strikt het uitgebreide procestoezicht op basis van ons kwaliteitsprocescontrolesysteem, dat het ontwerp van producten bevat , onderzoek en ontwikkeling, testen, productie, kwaliteitsinspectie en verpakking.

Onze laboratoriuminstrumenten en -apparatuur worden gebruikt in veel wetenschappelijke laboratoria, wetenschappelijke onderzoeksinstellingen, universiteiten, ziekenhuizen, centra voor ziektebestrijding en andere instellingen, en worden gecombineerd met vele bekende biofarmaceutica, nieuwe energie, elektronicabedrijven, voedselverwerking, milieubescherming, enz. Samenwerking tussen bedrijven, onze stabiele en betrouwbare producten worden geëxporteerd naar meer dan 120 landen over de hele wereld en worden door hen zeer erkend, geloof LABOAO, we groeien samen!