DETAILS

- Control box, can show vacuum pressure, temperature and speed

- Main evaporator, SUS material, better thermal conductivity, good evaporation effect and not easy damage

- Jacket feeding tank, jacket can through fluid to warm material in advance

- Condenser+cold trap system, windows design, easy to observe material process program, gas condenses more thoroughly

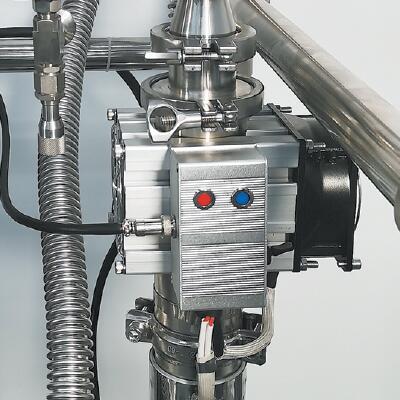

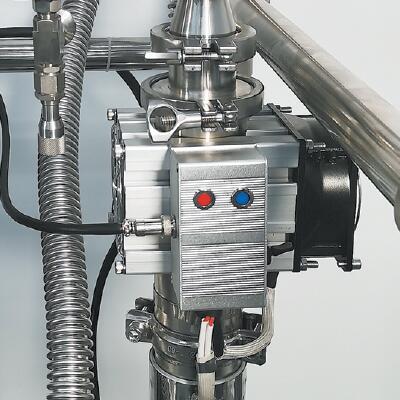

- Inlet and outlet pump, continuous feeding and discharging to improve work efficiency

- Diffusion pump, can improve vacuum degree to 0.01Pa

DESCRIPTION

Molecular distillation is a special liquid-liquid separation equipment. Unlike traditional distillation, it relies on the boiling point difference separation principle, but on the difference of the average free path of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules will escape from the liquid level and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances move different distances after escaping from the liquid level. After passing through the built-in condensate pipe of the main evaporator, the light molecules reach the condensate pipe and are discharged, while the heavy molecules cannot reach the condensate pipe and are discharged along the mixed liquid, So as to achieve the purpose of material separation.

Working Principle

The materials are transported from the feed tank to the jacketed main evaporator. The main evaporator is continuously heated. The built-in scraper evenly scrapes the materials into a layer of flowing liquid film for instant evaporation. The light component materials begin to vaporize and adsorb on the built-in condensing coil, flow into the receiving bottle along the outer wall of the condensing pipe, and the heavy component materials flow into the receiving bottle along the inner wall of the main evaporator.

Application

Extraction of deep sea fish oil |

Extraction of CBD oil |

Pharmaceuticals |

Concentration of plant essential oil |

Separation of vitamin / nutritional essential oil |

Chemical Research |

FEATURES

1. Modularized design for flexible options

2. Continuous feeding & collection modules design, saving labor cost and working time

3. Fully jacketed design, wide applications for different materials

4. SUS316L stainless steel, safe and reliable

5. Sight glass and quick connect design, easy to disassemble and clean

6. The unique design of the plate heating method can better heat and keep the materials and protect the materials from being oxidized.

7. Gear pump automatic feeding, stable speed, long service life, no air leakage

SPECIFICATIONS

Model | LSMD-0.1 | LSMD-0.15 | LSMD-0.25 | LSMD-0.35 | LSMD-0.5 | LSMD-1 | LSMD-1.5 | LSMD-2 | LSMD-3 | LSMD-5 |

Condenser area (㎡) | 0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 | 8 |

Effective evaporation area (㎡) | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1 | 1.5 | 2 | 3 | 5 |

Feeding rate (LH) | 5~12 | 6~15 | 10~25 | 15~30 | 20~60 | 50~120 | 60~180 | 100~200 | 100 ~300 | 200 ~500 |

RPM (r/min) | 30~350 |

Stainless steel material | 304/316 |

Feeding method | Gear pump automatic continuous feeding |

Discharge method | Gear pump automatic continuous discharge |

Work temperature | Within 350℃ |

Voltage | 200V 50Hz (can be customized) |

WAAROM VOOR ONS KIEZEN

- Directe verkoop in de fabriek met een concurrerende prijs.

- Premiumkwaliteit met CE- en ISO-certificering.

- Sterke OEM- en ODM-aanpassingsmogelijkheden voor producten.

- Beloof productie en tijdige levering.

- Perfecte klantenservice, gratis productaccessoires.

- 15 jaar ervaring in R&D en productie van molecular distillation system machine.

ONZE FABRIEK

We hebben een standaard productiewerkplaats en een compleet productieteam. Ze produceren altijd een serieuze en verantwoordelijke houding om elk product te produceren. Ons R & D-team bestaat uit professionele ingenieurs met meerdere aspecten, zoals ontwerpingenieur, technologiespecialist, gekwalificeerde specialist en procescontrolemanager, enz. Onze gekwalificeerde specialisten realiseren strikt het uitgebreide procestoezicht op basis van ons kwaliteitsprocescontrolesysteem, dat het ontwerp van producten bevat , onderzoek en ontwikkeling, testen, productie, kwaliteitsinspectie en verpakking.

KLANTGEVALLEN

Onze laboratoriuminstrumenten en -apparatuur worden gebruikt in veel wetenschappelijke laboratoria, wetenschappelijke onderzoeksinstellingen, universiteiten, ziekenhuizen, centra voor ziektebestrijding en andere instellingen, en worden gecombineerd met vele bekende biofarmaceutica, nieuwe energie, elektronicabedrijven, voedselverwerking, milieubescherming, enz. Samenwerking tussen bedrijven, onze stabiele en betrouwbare producten worden geëxporteerd naar meer dan 120 landen over de hele wereld en worden door hen zeer erkend, geloof LABOAO, we groeien samen!